Everyone has heard the old saying “A chain is only as strong as its weakest link”. Well that can relate to trees as well. You can say that “A tree is only as strong as its weakest union.” Most of the branch, trunk and canopy failures that we come across are a result of a weak union. Co-dominant stems, cavities and included bark in unions are the most common aggravating factors that cause trees to fail. Our Isa certified arborists are experts in locating and identifying these structural defects. Once our Arborist has identified a structural defect he will develop a plan to help mitigate the risk. The installation of a supplemental support system is usually recommended. Every tree is unique, and will require a different supplemental support design. The following issues are commonly found in urban trees around the charlotte area. Please take a minute to look over the structural problems and the various types of support systems that we install to mitigate the risk.

Typical Structural defects

Co-dominant stems

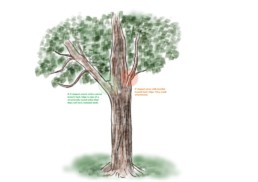

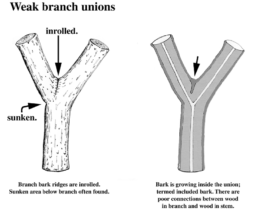

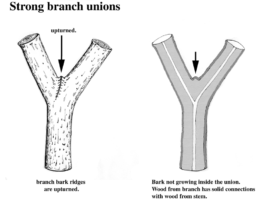

Co-dominant stems are found in almost every property and they are probably the most common structural defect found in the trees around Charlotte. The term “co-dominant” is self-explanatory. It is when two or more stems from a single tree attempt to “dominate” or compete for dominance of the parent stem. To put simply, it is when a tree trunk splits into two or more sections. This isn’t always a terrible thing, but it could elevate a trees probability of failure and it should be inspected by a certified arborist. We take several things in to consideration when inspecting a co-dominant union. We look at the shape of the union first. We like to see a U shaped union and not a V shaped one. If the union of the tree has a V shape, the union is probably weakened and a supplemental support should be installed. If the union has a U shape, the probability of failure isn’t as high. Our primary point of focus is the “Branch bark ridge” or marriage line when we inspect V shaped unions. A rise or upturn on the ridge is a good indicating factor that the union does not have bark inclusion. However, if the marriage line turns inward there is probably included bark and a supplemental support system should be considered. .

Cracks in unions

Cracks can occur in co-dominant unions as a result of high wind, ice loading, or simple effects of gravity. They are hard to see from the ground in most cases and can go undetected for years. Scar tissue in branch unions is a key sign of a crack that has begun to heal. This tissue usually only helps the vascular system seal itself off and doesn’t aid in supporting the compromised wood

Cavities

Cavities and holes in limbs, trunks or branches are points of weakness. Cavities and holes can severely compromise a tree’s structural integrity. All cavities should be inspected by an arborists as soon as they are located.

Types of support Systems

Cabling

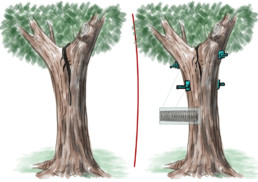

Tree cabling is a process of installing cables or wires and connectors to help reduce the probability of branch, trunk or whole tree failure. Supplemental support systems are used to help support a damaged or structurally compromised tree. Trees that have cracks, cavities or other aggravating factors such as co-dominant unions or stems are candidates for cabling.

There are two basic types of cabling systems.

Static Cabling– (EHS) Extra High strength steel cable or wire that does not stretch is typically used in static cabling systems. These systems are installed when no give or play in the union is desired. There are a variety of ends that are used to attach the wire to the stem of the tree. Eye hooks, specialty connectors and lag bolts are a few that we use frequently.

Determining the exact point where the cables will be installed is the first step in the installation process. Once that has been done the specified wires and or cables will be installed. They are placed 2/3–3/4 of distance between the union and end of the branch. After the location is determined the fasteners are installed. If the cable system requires lag hooks hey can simple be screwed into the tree. If a wire stop or through eye bolt is required then a hole must be drilled and the rod or wire inserted.

Dynamic Cabling- Dynamic systems use a braided specialty rope with elastic qualities to allow for movement. As trees move with the wind they build more wood. Dynamic systems are a great proactive system to prevent failure but may not be the best for mitigating a tree that has already began to fail.

Bracing

Bracing is a lot like cabling. Bracing rods are usually installed close to the union or crotch. It is a pretty straight forward process. Determining the size and number of the rods needed to properly support the weight of the tree is the first step in the bracing process. A come-along or other tensioning device will be used to close the crack if a tree possesses a large amount of separation. Once that is complete, the holes will be drilled in the appropriate spots. Each hole is drilled about 1/16 of an inch smaller than the size rod that going to be used. This will ensure that the rod fits securely in the hole. Once the holes are drilled, the threaded steel rod will be inserted. Washers and Nuts will be installed to secure finish it off. Cabling and bracing are often done together.